Weaving Loom Buying Guide

Published on August 25, 2023 13 min read

Looking to get started with weaving or returning to weaving after a break but not sure where to begin? We can help! Our Weaving Loom Buying Guide is here to walk you through the different kinds of looms we sell and help you choose one you're sure to love.

Considerations When Buying a Loom

What do I want to weave?

Looking at what kinds of pieces you want to weave is a great starting place for determining what loom would be best for you. The size of the loom will prescribe the types of woven projects in 2 ways—the weaving width of the loom and the types of cloth woven. The complexity of the patterns is determined by the number of shafts and/or the time and willingness to use hand-manipulated techniques.

Let’s start by talking about the weaving width of the loom, this number indicates the widest warp that can be woven on the loom. What’s often left out are 2 key pieces of information:

- The woven cloth will be narrower due to shrinkage (from wet finishing) and take up (the amount the fabric draws in). This means your finished piece will be anywhere from 10 – 25% smaller, depending on the fiber content and weave structure.

- Weaving the full width of the loom is not always advisable, as the beater works best with some space on either side. Many weavers keep their warps 1 -2” narrower than the full width to get the best leverage with the beater.

The upshot of this is that you need to think about the sizes of the kinds of projects you want to weave. Here are some general guidelines:

10” loom — scarves, bags and table runners

15”–20” loom — scarves, shawlettes, table runners, placemats, narrow dish towels, bags, fabric to piece into clothing and blankets

25”–30” loom — all of the above plus standard dish towels, baby blankets, throws, shawls, rugs*

36” – 59” loom — all of the above plus tablecloths, coverlets and full-size blankets Note: On most looms with a shedding mechanism, including some rigid heddle looms, you can increase the width of your cloth using double weave, though this can limit your pattern and design options.

*On rugs: Generally speaking, it is advisable to weave rugs using heavier looms. It can be challenging, though not impossible, to weave rugs on lighter looms such as a rigid heddle or Wolf Pup/Baby Wolf. If rugs are something you want to weave a lot of, however, consider a heavier loom.

Bigger is not always better! Handweaving is a physical craft and you want to be sure it is comfortable and enjoyable. How far can you comfortably throw a shuttle, can you easily reach all the treadles? And—this is the big question—what will you be weaving most of the time? In other words, buy the loom that fits 80% of your projects. A loom that is too big can make extra work and be physically cumbersome. Just as your warp has a sweet spot for weaving, find a loom that fits the sweet spot in your project list.

Space

How much room do you have for a loom? Some looms have a large footprint and need a dedicated space when set up. Others are small, portable, or fold up, making them easy to store when not in use.

Our looms, from smallest to largest:

- Tapestry, Inkle, Frame, Pin and Card/Tablet looms — These small looms take up very little space and are easy to store and transport. They are small and simple enough for children to use (get them started young!), while offering much for the experienced weaver as well. Some tapestry looms can be slightly larger, but usually sit on an A-frame stand on a table.

- Rigid Heddle (RH) Looms — some can fold for storage, even with a warp on. Schacht Cricket looms are small RH looms with either a 10” or 15” weaving width. These looms do not fold but are small for easy storage and transport. They have an optional stand or can be placed in the lap or on a tabletop for weaving. Schacht Flip looms range from 15”–30” weaving width. They fold in half easily, even while warped, for easy storage and transport. These looms also have a stand, highly recommended for looms 25” and wider, and the loom can be stored on the stand or taken off and folded.

- Multi-shaft Table Looms — can fold for storage, even with a warp on. Table looms are a good choice for multi-shaft weaving when you don’t have a lot of space. Both of the table looms we offer, Louët Jane and Louët Erica, will fold when not in use (even with a warp on), allowing you to store them out of the way. Although these looms can sit on the table for weaving, the angle can be uncomfortable and most weavers will stand or use a tall stool while weaving. Both of our table looms have stands you can order separately, which put the loom at a better height for weaving while seated.

- Folding floor looms (Schacht Wolf loom series) — can fold for storage, even with a warp on. The Schacht Wolf series of looms all fold up easily, making them a good choice for those with smaller spaces. Open them out while weaving, fold them and tuck them to the side when you need the space. They also make great looms for workshops due to their size and portability. The Wolf Pup LT comes with built-in wheels on one side and the Baby Wolf and Mighty Wolf have a stroller attachment that adds multi-directional wheels to all 4 legs that engage when the loom is folded and disengage when the loom is unfolded for weaving.

- Floor looms — The footprint of a floor loom will depend on the weaving width and the manufacturer. Our smallest floor loom is the Louet David (small but mighty!) which comes in 2 widths (27.5” and 35”) and has a compact size when compared to other floor looms with similar weaving width. The Schacht Standard also comes in 2 widths – 36” and 46” - and a slightly larger footprint. Our largest looms are the Toika Countermarch and Computer-assist looms. These Finnish looms are big and sturdy and require a large, dedicated space. Weaving widths vary from 32”–59” and the loom width is about 14” wider; the depth of these looms is 59”. The Toika looms also have a castle that is over 5’ tall, so the height needs to be taken into consideration as well.

Complexity

In general, the more shafts a loom has, the more complex the patterning can be. At the same time, weavers can, and do, push the limits of their looms with hand manipulations and other techniques to expand the possibilities.

The simplest looms are those with 2-shaft capabilities—Rigid Heddles, Inkles, Tapestry looms. They produce what is called ‘plain weave’—simple over/under alternation of threads. The weaver can create more complex patterns using pick up sticks and other hand-manipulated techniques to weave lace, textured patterns and more.

Multi-shaft looms may have anywhere from 4 to 32 shafts. With the increasing number of shafts comes an exponential increase in the number of pattern possibilities. But more is not necessarily better! More shafts often means more concentration to keep track of the threading and treadling. When considering the number of shafts you want for your loom, look at the types of patterns/weave structures that you really like and want to weave. Remember that you can always use less than the total numbers of shafts available.

4- and 8-shaft looms are the most common configuration and allow for a huge variety of patterns and weave structures. It is easy to find drafts for these looms. A 4-shaft can be simpler to start with yet has more than enough possibilities to keep a weaver satisfied for life. And some people choose to start with an 8-shaft because they know from the beginning that they want to weave more complex patterns.

Our largest looms, with 16–32 shafts, come with a computer-assist to help with treadling and threading. Weaving software is used to design and import drafts and drive the loom. The control box lifts the shafts with the tap of a single pedal. The weaver is freed from crawling under the loom to tie up shafts and no longer has to remember treadling sequences and lift heavy shafts. More time for the fun stuff!

Price

As with most things, the bigger and more complex a loom is, the higher the price. The simplest looms, like the Inkle and Rigid Heddle looms, are the least expensive and as you add shafts and weaving width the cost goes up. It can feel daunting to look at the equipment costs but remember you are investing once in a tool that can take you through your weaving lifetime. It’s not like knitting needles where you have many sets! A thoughtful choice will last many years, so it’s good that you are doing your research now.

There are also ways to make it more manageable. One is to start small while you decide if weaving is something you want to continue with. Rigid Heddle looms are an inexpensive way to begin weaving and test the waters. We also offer looms from Schacht that start with 4 shafts and can be expanded to 8 shafts later (called the 4 now 4 later), allowing a lower initial investment.

Buying a used loom can feel like a cheaper way to get started but it can be risky because it’s hard to assess the condition of the equipment when you’ve never used it. Often, the looms have been stored in poor condition and things are warped or rusted. The benefits of buying a loom new are that you get the support and service of the dealer and parts are easy to obtain.

In addition, all our new looms come with warranties from the manufacturer. All Schacht floor looms (the Standard and the Wolf Series) come with a 2-year limited warranty. All Louët looms (table looms and floor looms) come with a 3-year manufacturer's warranty. All Toika computer-assist and manual looms come with a 2-year limited warranty.

Ease of entry

There are several factors that will affect how easy it is to get started weaving. The main one is the learning curve for the loom in question, and the complexity of the loom is a big part of it. Learning the basics in a class or workshop should set you up with the information to continue on your own.

For many of the smaller and/or simpler looms, there are fewer steps in setting up and weaving so it takes a shorter time to learn the basics and get weaving on your own. Rigid Heddle looms, small frame looms, pin looms, cards and Inkles all fall into this category. Many people also teach themselves with books or online videos.

Multi-shaft looms involve a lengthier process, with many steps to get the warp on the loom. Although some people learn from watching videos, we recommend a class as it will allow you to ask questions and get advice as you learn. We offer weaving videos on our YouTube channel.

Types of Looms

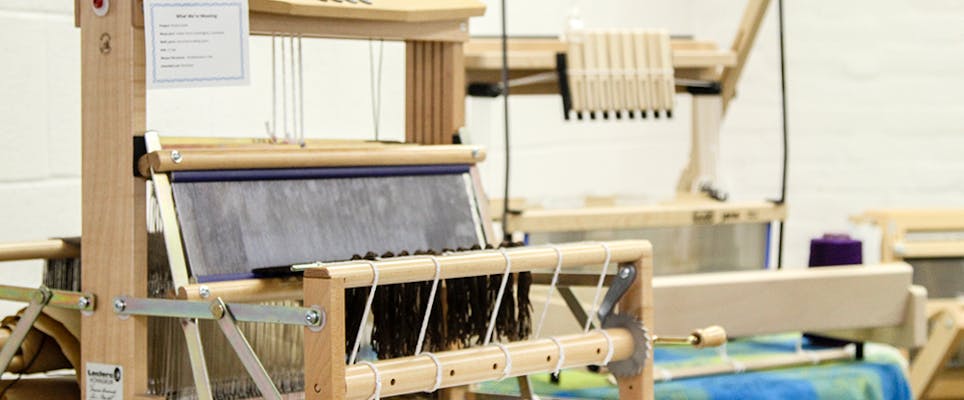

FLOOR LOOMS

Floor looms can have anywhere from 2 to 32+ shafts. They are operated with foot treadles or a control box (for computer-assist). Some floor looms fold up when not in use for easy storage or transport. There are three basic categories of floor looms: jack looms, countermarch looms and counterbalance looms. See below for more detail.

Jack

Jack looms are very common and each shaft is able to operate independently. Most jack looms are rising shed looms, the treadle is connected to the jack which lifts the shaft when the treadle is pressed. The top threads are taut and the bottom threads are looser, so jack looms will have a shuttle race to support the shuttle as it travels across the warp.Most jack looms will have metal heddles as the weight helps pull the shafts back down when the treadle is released. This makes these looms louder than those with nylon heddles and adds weight to the treadling.We also have a sinking shed jack loom, the Louet David. On this loom the treadles pull the active shafts down and the other shafts stay up. This creates a large shed like a countermarch, with the bottom threads taut. This loom uses the Texsolv heddles so it is very quiet.

Countermarch

In a Countermarch loom each treadle is tied to every shaft and when a treadle is pressed the active shafts rise and all other shafts sink. This produces a beautiful, large shed where the top and bottom threads are equally tensioned and no shuttle race is needed. Countermarch looms are quieter because they use nylon heddles which also make them lighter to treadle. Many countermarch looms have large frames and an overhead beater, making them well suited for rugs and other projects that require heavy beating. The Toika looms that we carry (Eeva, Liisa, Jaana and Laila) are all countermarch looms.

Counterbalance

Counterbalance looms operate with a system of pulleys and/or horses such that when one shaft goes up, another goes down; each treadle will move every shaft either up or down. This creates a great shed with both top and bottom threads taut and eliminates the need for a shuttle race. Although it is possible to weave unbalanced patterns on a counterbalance loom, the shed will not be as good, though some companies have created shed regulators to help. WEBS does not sell any counterbalance looms.

TABLE LOOMS

These multi-shaft looms sit on a table, though some table looms have stands available. Shafts are lifted using hand levers. Table looms are lighter weight and more portable than floor looms and most will fold up as well.

RIGID HEDDLE LOOMS

Rigid Heddle looms are 2-shafts looms with an all-in-one heddle/beater made of rigid plastic. Though made for plain weave cloth, complex patterns can be created with hand manipulation of the warp, assisted by pick-up sticks and/or additional rigid heddles. Rigid heddle looms can be used on a table or with a stand.

TAPESTRY LOOMS

Tapestry and Frame looms are made for weft-faced weaving where the warp is hidden. The warp is wrapped around the frame under high tension and the weft is inserted over and under with a needle, small bobbin or by hand, and then packed into place with a hand beater.

INKLE LOOMS

Inkle looms produce narrow (2” - 5”) warp-faced pieces. Looms are small and portable and use string heddles and tiny belt shuttles.

CARD WEAVING

Weaving cards can be used with a simple box or backstrap loom or on an inkle loom. The warp yarn is threaded through holes in the cards and the cards are rotated, individually or as a pack, to create the sheds for weaving. The resulting pieces are warp-faced and tend to be narrow.

Featured Looms

Schacht Flip Rigid Heddle Looms